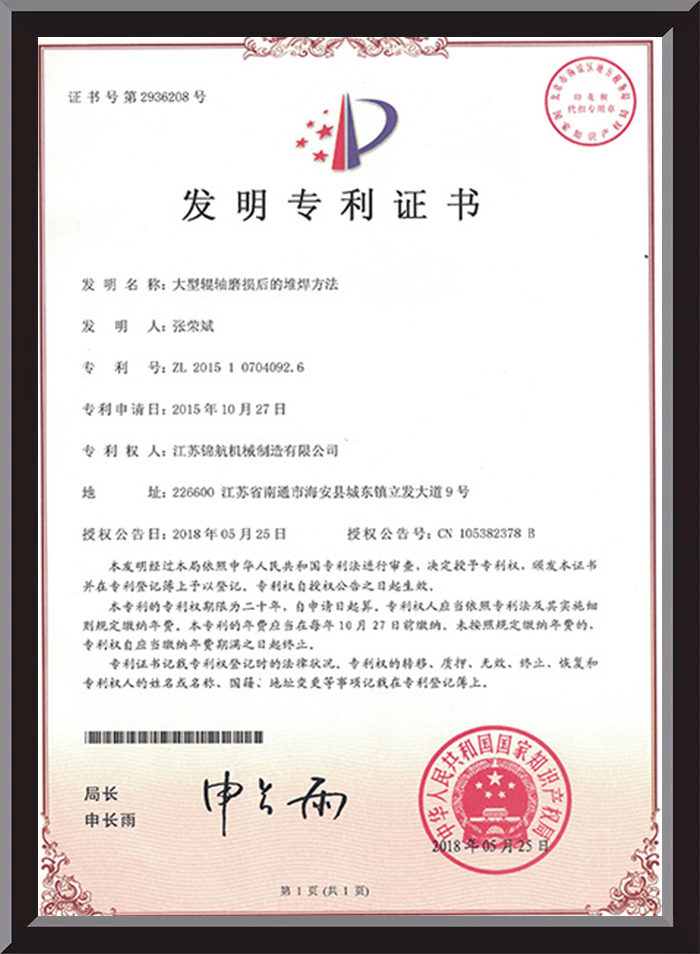

Founded in 2001, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. has obtained the ISO9001 Quality Management System Certification. We are committed to the R&D and manufacturing of various roll types with different roll body structures. In accordance with the requirements of mechanical equipment, we can design rolls that meet the application needs. As a famous China Low temperature resistance hypalon rubber rollers Suppliers and Low temperature resistance hypalon rubber rollers Factory, we also provide custom processing services, enabling us to carry out custom manufacturing based on your drawings.

The goal of Jinhang Machinery is to design and manufacture efficient, stable and durable rolls within a reasonable budget. Each roll undergoes quality tracking and inspection at different process stages, and only after passing the inspection can it proceed to the next process, ensuring that all rolls meet the quality requirements before leaving the factory. We also provide reliable and practical after-sales services. Within the warranty period, for any quality issues that occur under the mechanical conditions specified in the drawings, we will provide free repair or replacement of the rolls.

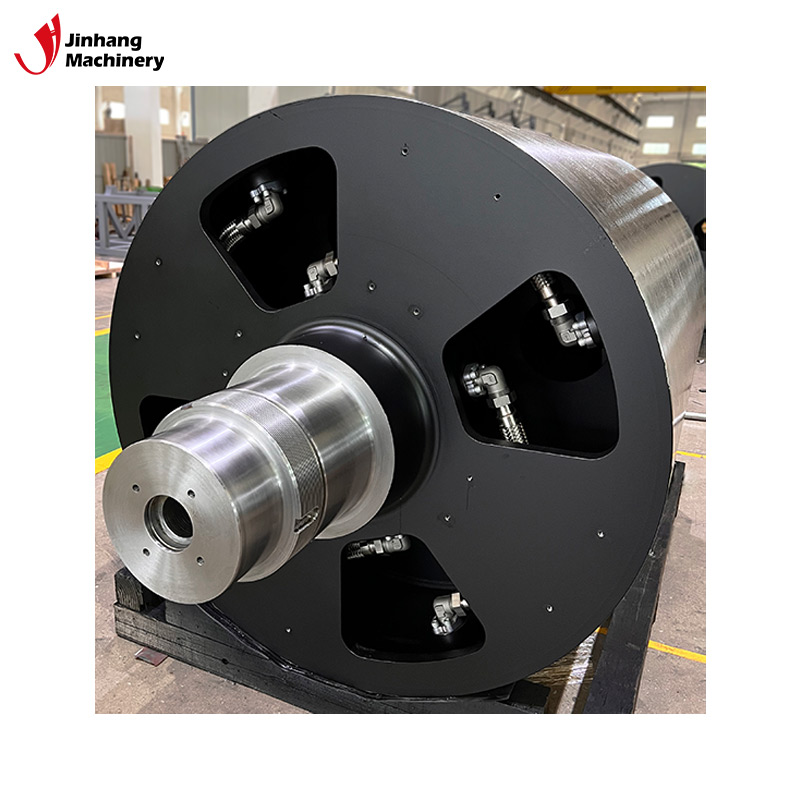

Currently, the company has a standard workshop covering an area of 13,000 square meters and a team of over 60 employees. Our equipment lineup includes CW61190, 61160, 61120, 61125 and 6180 lathes, imported Italian POMINI universal grinding machines, 1380, 1363 and 1350 grinding machines, 160 and 110 boring and milling machines, vertical milling machines, drilling machines, dynamic balancing machines, plate bending machines, automatic welding machines, as well as domestically advanced polyurethane casting machines and fully automatic environmental protection sandblasters.

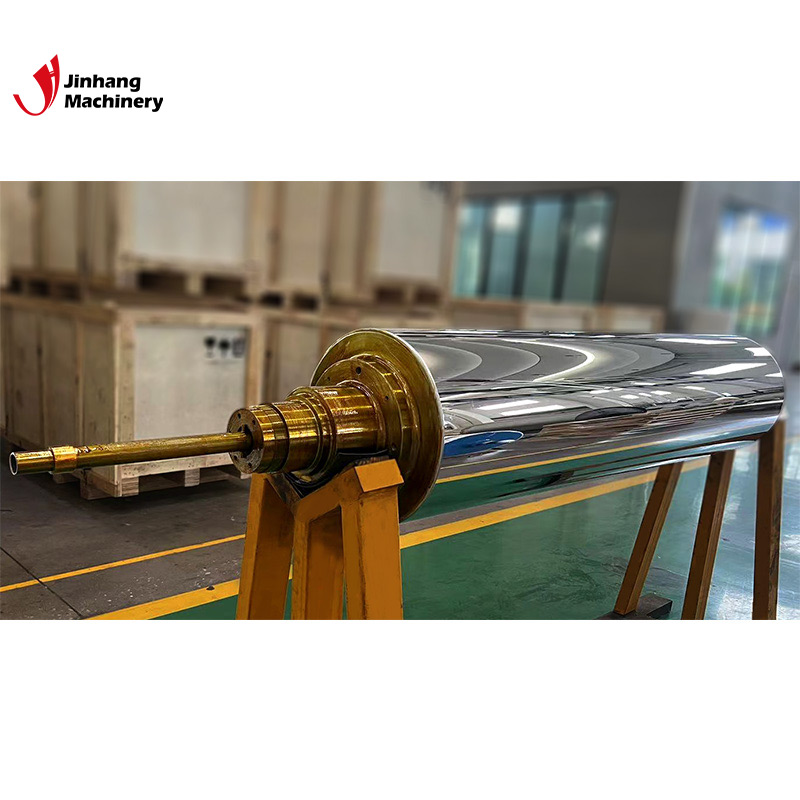

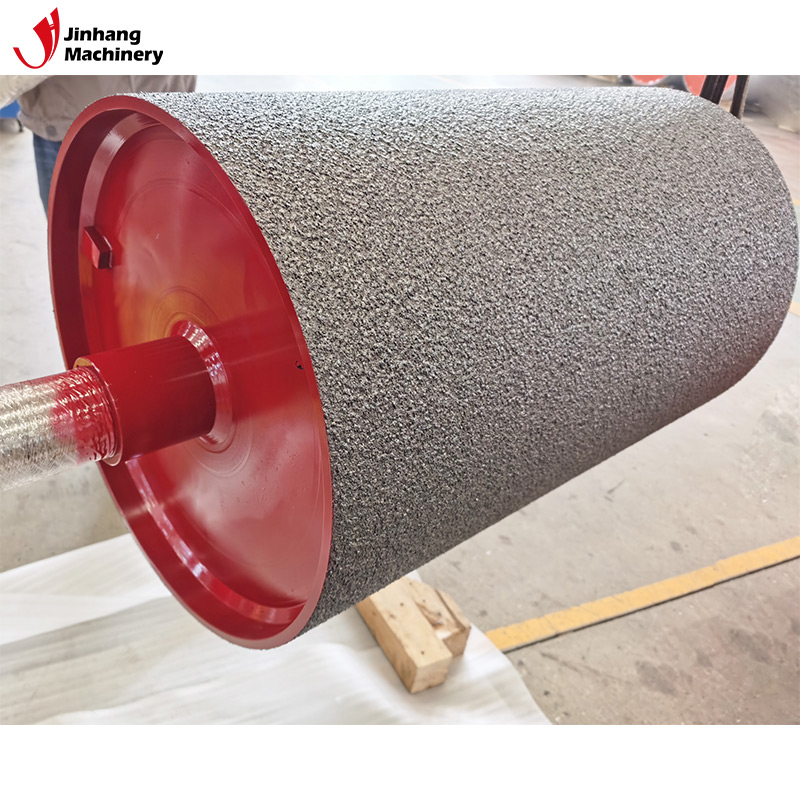

We specialize in manufacturing and processing various high-precision rolls with strict requirements, including various rubber rolls, polyurethane rolls, heating rolls, mirror surface rolls, chill rolls, corona rolls, ceramic anilox rolls, chrome-plated rolls, tungsten carbide rolls, and other various customized carbide-coated rolls and special roll shapes. Our products are widely applicable to industries such as metallurgy, mineral processing, packaging, printing, lithium battery manufacturing, and automotive testing equipment.

Low temperature resistance hypalon rubber rollers

When it comes to durability, Low temperature resistance Hypalon rubber rollers are second to none. Their exceptional wear resistance ensures a long-lasting performance, significantly reducing the need for frequent replacements. This means less downtime for your operations and more cost savings in the long run. Whether it's handling abrasive materials or operating under high-friction conditions, our Hypalon rubber rollers can withstand the test of time, maintaining their shape and functionality. In addition to their wear resistance, these rollers also boast excellent heat resistance. They can operate efficiently in high - temperature settings without degrading or losing their mechanical properties. This makes them ideal for applications where heat is a by - product of the process, such as in printing, coating, and laminating industries. But what truly sets our Hypalon rubber rollers apart is their outstanding low - temperature resistance. Even in extremely cold conditions, they remain flexible and maintain their grip, ensuring smooth and consistent operation. This makes them perfect for industries like food processing, where refrigeration is common, or outdoor applications in cold climates. From printing presses to conveyor systems, our Hypalon rubber rollers find a wide range of applications. So, if you're in need of high-performance rollers that can handle a variety of challenging conditions, look no further than our Hypalon rubber rollers. Invest in them today and experience the difference they can make to your operations.

English

English русский

русский Deutsch

Deutsch