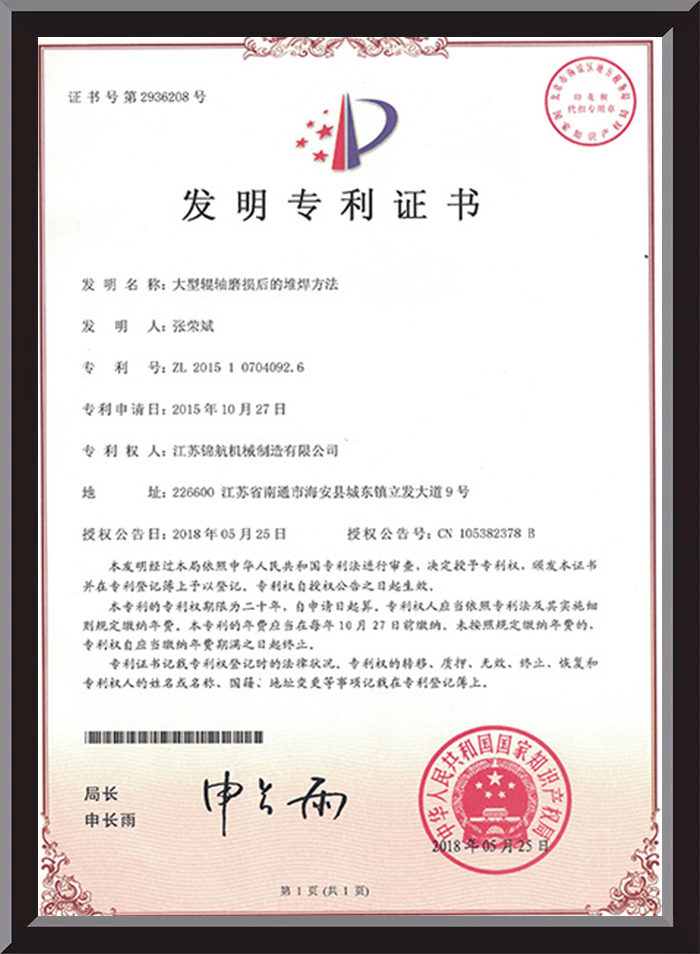

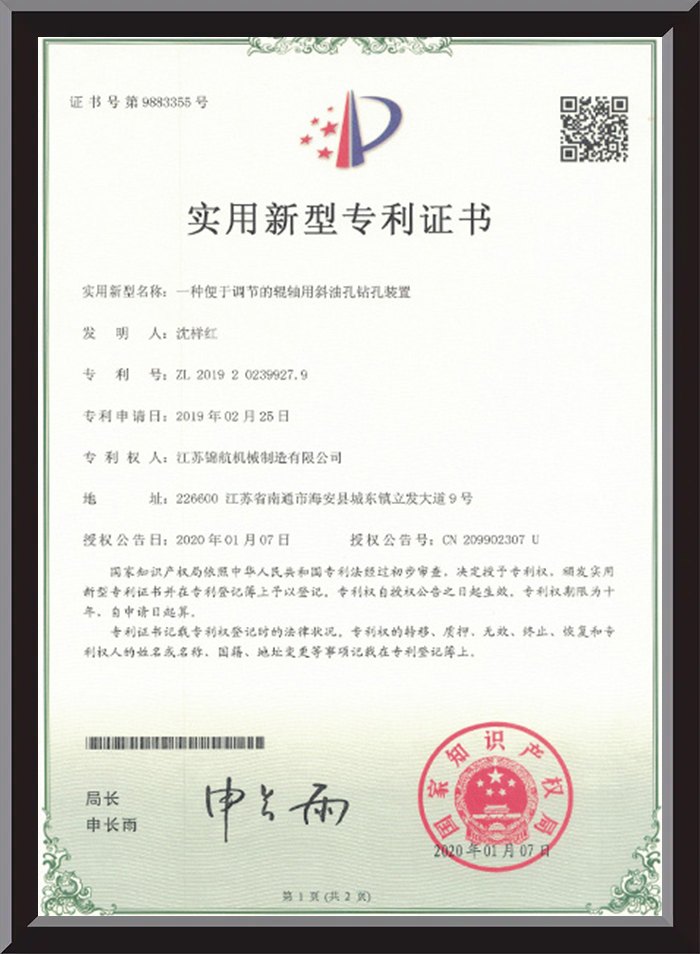

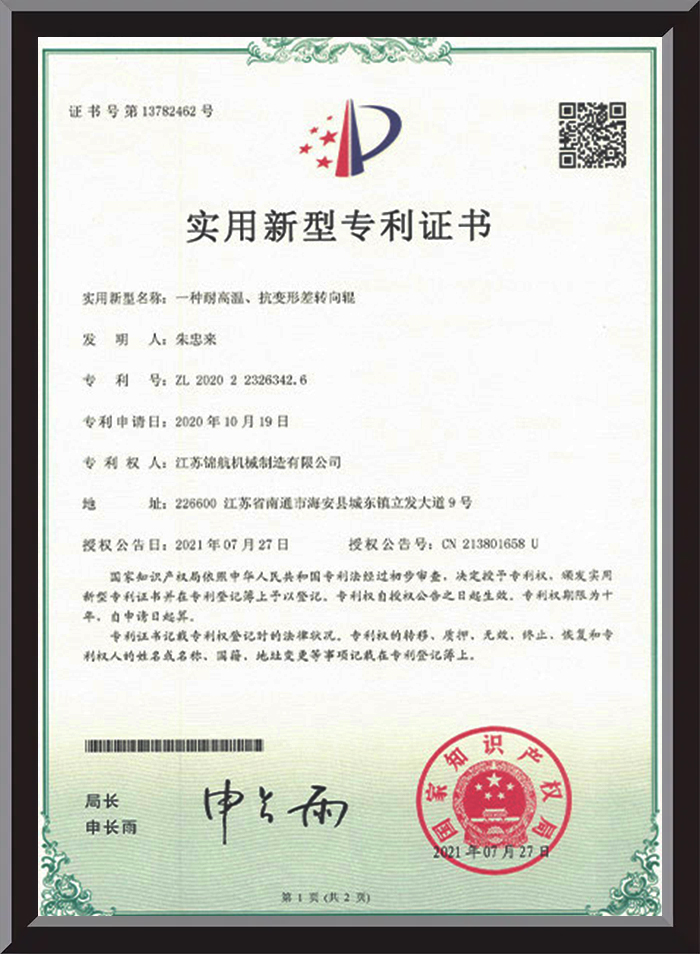

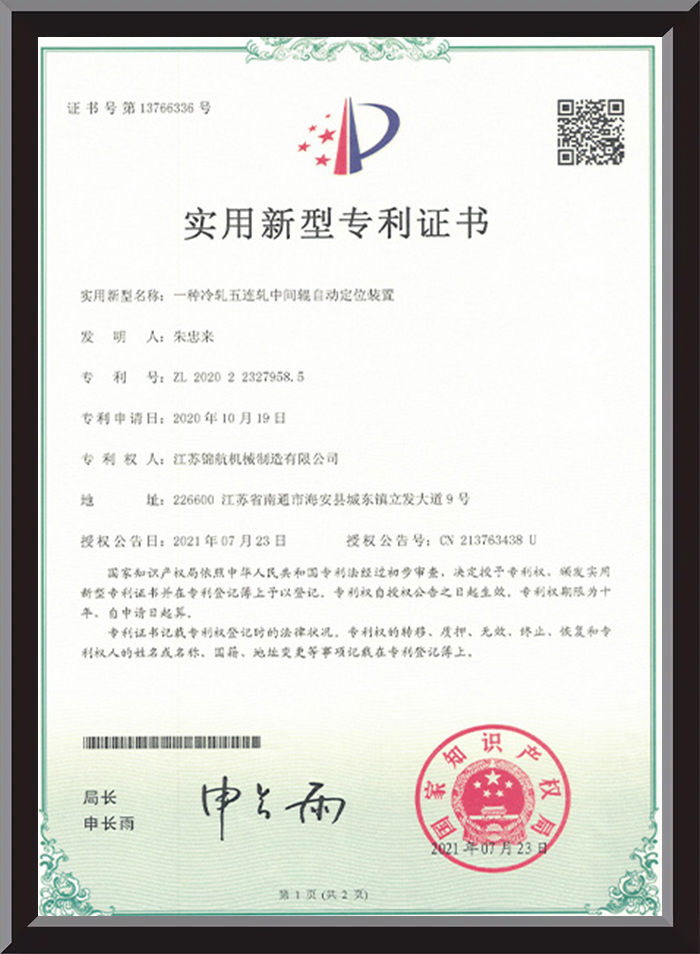

Founded in 2001, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. has obtained the ISO9001 Quality Management System Certification. We are committed to the R&D and manufacturing of various roll types with different roll body structures. In accordance with the requirements of mechanical equipment, we can design rolls that meet the application needs. As a famous China Uniform cooling mirror cooling roller Suppliers and Uniform cooling mirror cooling roller Factory, we also provide custom processing services, enabling us to carry out custom manufacturing based on your drawings.

The goal of Jinhang Machinery is to design and manufacture efficient, stable and durable rolls within a reasonable budget. Each roll undergoes quality tracking and inspection at different process stages, and only after passing the inspection can it proceed to the next process, ensuring that all rolls meet the quality requirements before leaving the factory. We also provide reliable and practical after-sales services. Within the warranty period, for any quality issues that occur under the mechanical conditions specified in the drawings, we will provide free repair or replacement of the rolls.

Currently, the company has a standard workshop covering an area of 13,000 square meters and a team of over 60 employees. Our equipment lineup includes CW61190, 61160, 61120, 61125 and 6180 lathes, imported Italian POMINI universal grinding machines, 1380, 1363 and 1350 grinding machines, 160 and 110 boring and milling machines, vertical milling machines, drilling machines, dynamic balancing machines, plate bending machines, automatic welding machines, as well as domestically advanced polyurethane casting machines and fully automatic environmental protection sandblasters.

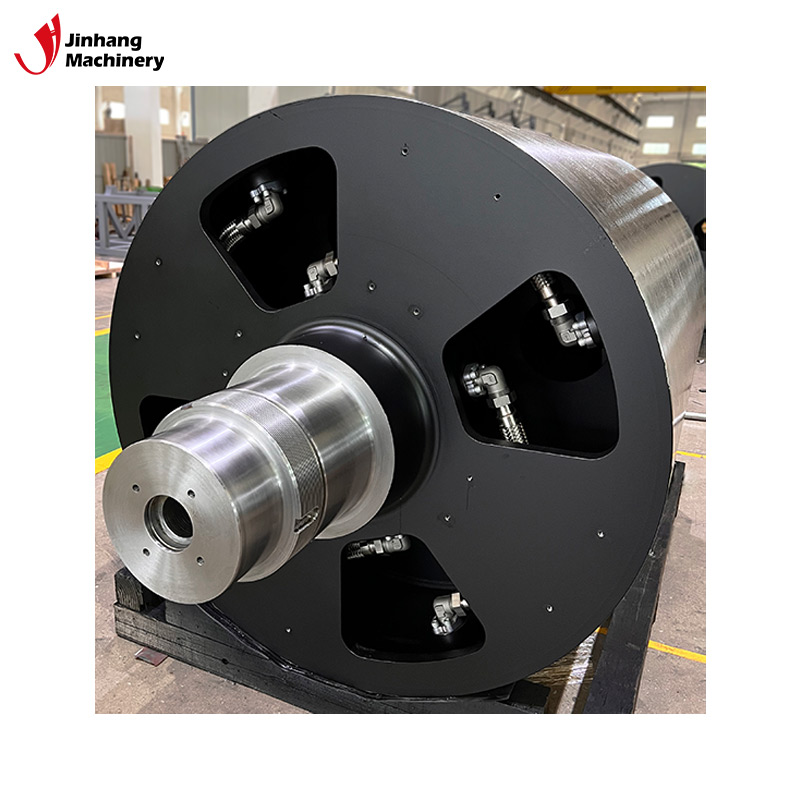

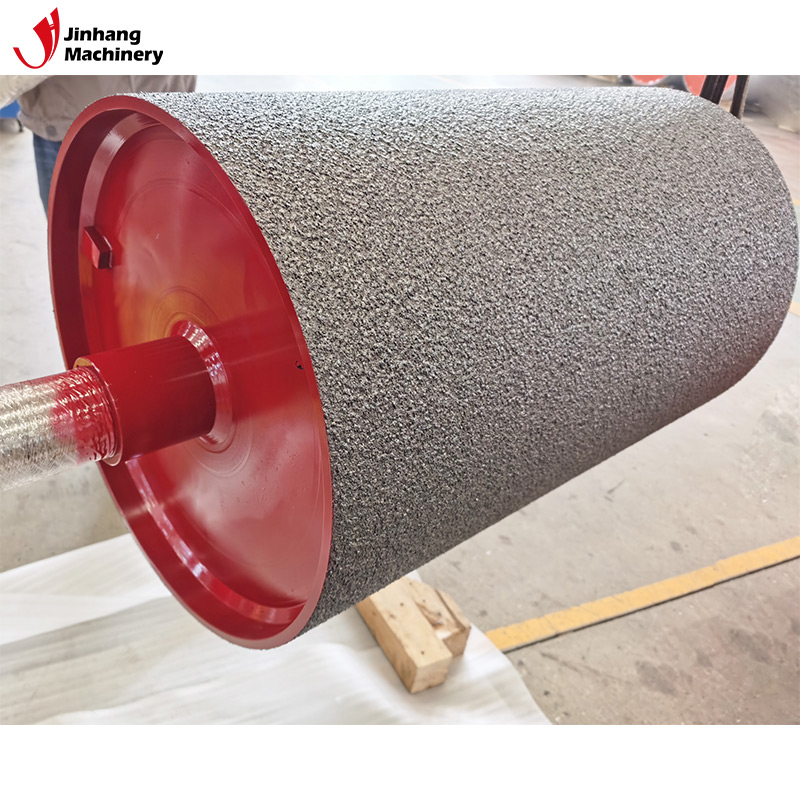

We specialize in manufacturing and processing various high-precision rolls with strict requirements, including various rubber rolls, polyurethane rolls, heating rolls, mirror surface rolls, chill rolls, corona rolls, ceramic anilox rolls, chrome-plated rolls, tungsten carbide rolls, and other various customized carbide-coated rolls and special roll shapes. Our products are widely applicable to industries such as metallurgy, mineral processing, packaging, printing, lithium battery manufacturing, and automotive testing equipment.

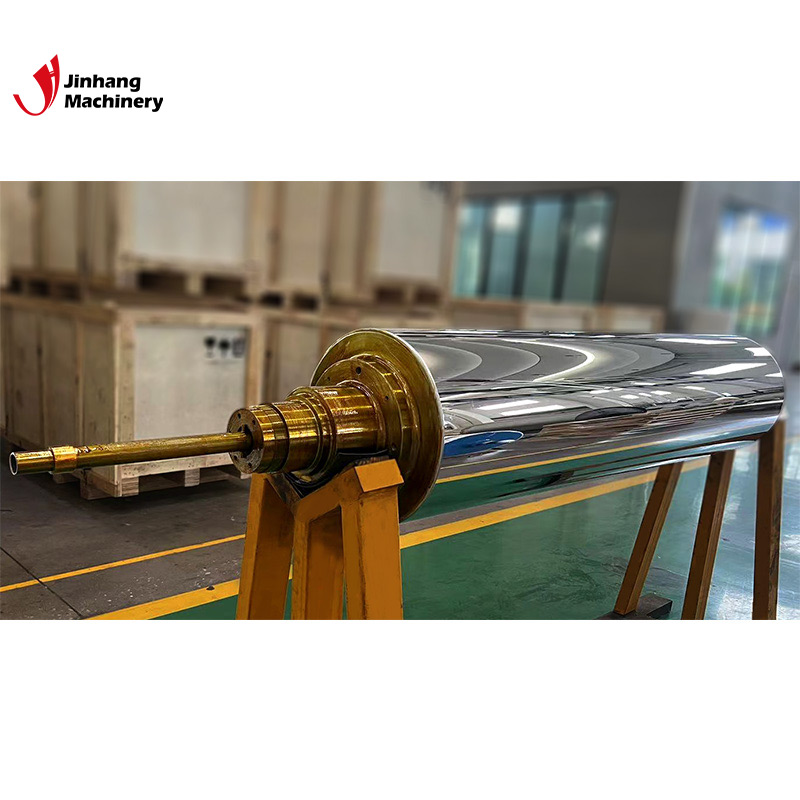

Uniform cooling mirror cooling roller

The Uniform Cooling Mirror Cooling Roller is a high-precision, mirror-finished roller designed for efficient and consistent cooling in high-speed production environments. At its core, the roller ensures uniform temperature distribution across the surface, which prevents warping, sticking, or uneven thickness in processed materials. Its mirror-polished surface not only improves product clarity and surface finish but also enhances material release, reducing waste and downtime. In the food and pharmaceutical packaging industry, where hygiene, precision, and consistency are critical, this roller plays a vital role in cooling films and sheets used for packaging. The even cooling ensures that materials retain their intended shape, transparency, and barrier properties — essential for protecting sensitive products. Beyond packaging, the roller finds application in plastic sheet extrusion, film casting, and coating processes, where stable temperature control is crucial for quality. Its internal spiral or serpentine flow design enables rapid heat exchange, making it ideal for use in cleanrooms and high-volume production lines. Whether you're processing PET, PVC, PE, or multilayer composite materials, the Uniform Cooling Mirror Cooling Roller delivers reliability and performance.

English

English русский

русский Deutsch

Deutsch