Durability and Performance of Industrial Metal Rollers in Harsh Environments

In many industrial applications, metal rollers must withstand high-temperature environments that can significantly impact their structural integrity. For example, in steel mills or foundries, rollers are often exposed to molten metal or temperatures above 1000°C (1832°F). At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we recognize the importance of temperature-resistant materials for rollers operating under such extreme conditions. We select materials that have exceptional heat resistance properties, such as high-chromium steel alloys, which maintain their strength and hardness at elevated temperatures. Heat exposure can cause thermal expansion, which may lead to distortion or permanent deformation if the material cannot maintain its original dimensions. To mitigate this, we apply heat treatment processes such as quenching and tempering to our rollers, which increases their hardness and ability to resist thermal fatigue. Our team carefully monitors the thermal performance of each roller, ensuring that it can handle prolonged exposure to high temperatures without failure. In cold environments such as cold-rolling mills or refrigeration systems, the opposite challenge arises. Rollers exposed to extremely low temperatures may become brittle, which could lead to cracks or fractures during operation. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. ensures that our rollers remain tough and resistant to cracking in low-temperature conditions by using materials that retain their strength and flexibility, such as tool steels and high-carbon alloys. By employing the right combination of materials and heat treatment processes, we ensure that our industrial metal rollers provide reliable performance, whether exposed to extreme heat or freezing temperatures.

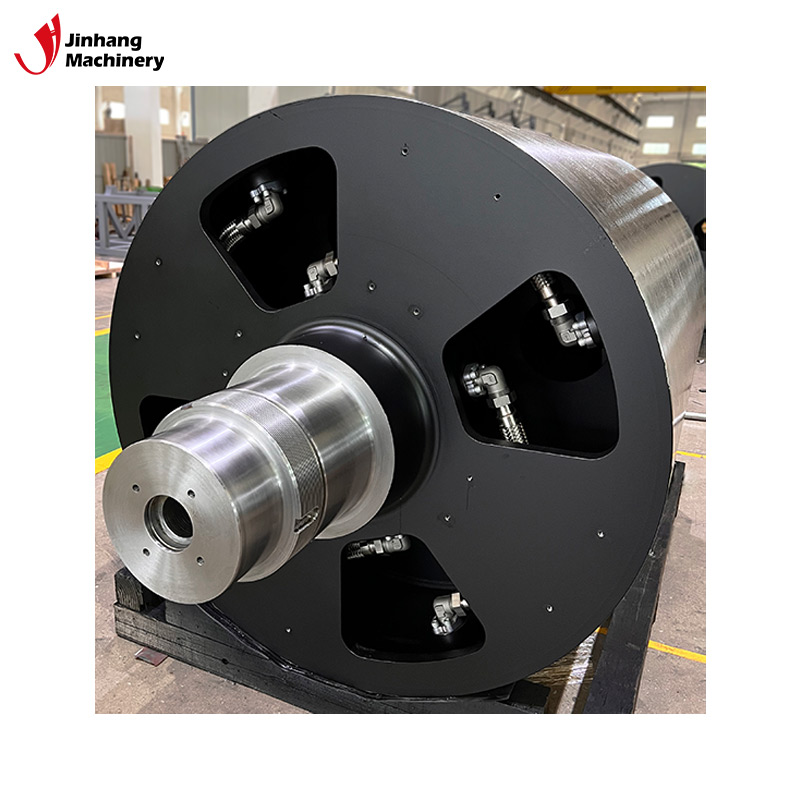

Industrial metal rollers are often used in applications that involve heavy loads and constant pressure. For instance, rollers used in mining, material handling, and steel processing equipment are subjected to tremendous mechanical forces, which can cause wear, deformation, or even catastrophic failure if the rollers are not designed to withstand such stresses. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we ensure that our rollers are engineered to handle these extreme pressures, providing businesses with components that maintain performance even under heavy load conditions. The first step in ensuring durability under heavy loads is selecting the right materials. We use high-strength alloys such as carbon steel and alloy steels that are specifically formulated to resist permanent deformation under high stress. These materials offer superior load-bearing properties, ensuring that our rollers can handle the weight and pressure associated with heavy-duty applications without losing their shape or functionality. We incorporate design optimizations, such as increasing roller diameter and adjusting geometry to distribute loads more evenly, which helps prevent stress concentration points that could lead to early failure. Our manufacturing process also includes forging techniques to improve material density and strength. Forged rollers are more uniform in structure and have improved mechanical properties compared to cast rollers. This added strength and durability are essential for rollers that operate under high pressures in applications such as heavy-duty conveyors or rolling mills. In addition to material selection and forging, we ensure that our rollers undergo rigorous testing to simulate real-world load conditions. By subjecting our rollers to dynamic load testing and impact simulations, we verify that they can withstand the extreme forces encountered in industrial operations without compromising their performance.

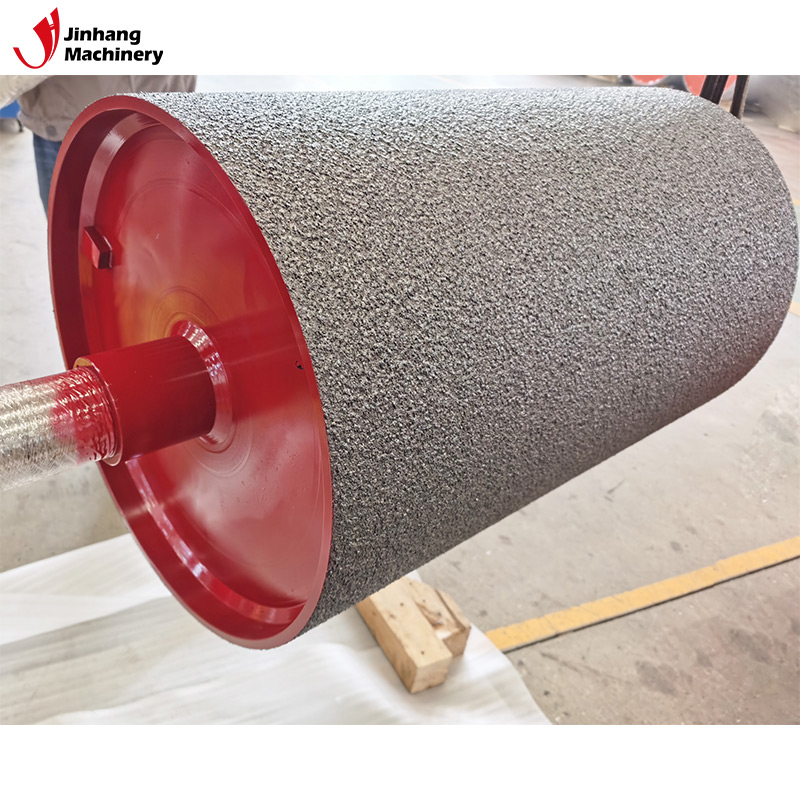

Abrasion is a common challenge for industrial metal rollers, especially in environments where they are exposed to rough or abrasive materials. Rollers in mining, cement manufacturing, and recycling industries, for example, are frequently in contact with abrasive particles like rocks, metals, or granular materials that can wear down the roller surface over time. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we prioritize wear resistance in the design and manufacture of our rollers to ensure they maintain optimal performance and longevity in high-abrasion environments. To combat abrasion, we utilize high-carbon steels and alloy materials that are inherently hard and resistant to wear. These materials provide the toughness needed to withstand the constant friction from abrasive substances. We apply surface treatments such as carburizing, nitriding, and induction hardening, which create a hardened outer layer that enhances the roller's wear resistance. These processes result in rollers with a hard, abrasion-resistant surface, while maintaining the toughness required to handle the mechanical stresses of daily operation. In high-abrasion environments, we offer specialized coatings such as ceramic coatings, tungsten carbide coatings, and chromium plating. These coatings create a durable surface layer that further reduces friction and resists wear, ensuring that our rollers maintain their functionality and performance over an extended service life. By choosing the right combination of materials and coatings, we ensure that our rollers are able to withstand even the most abrasive environments without significant deterioration. We also take into account the operational factors that affect wear, such as roller speed, load, and material type. By analyzing these variables and tailoring the roller design to each specific application, we ensure that our rollers offer the best possible resistance to wear and tear, reducing the need for frequent replacements and minimizing maintenance costs.

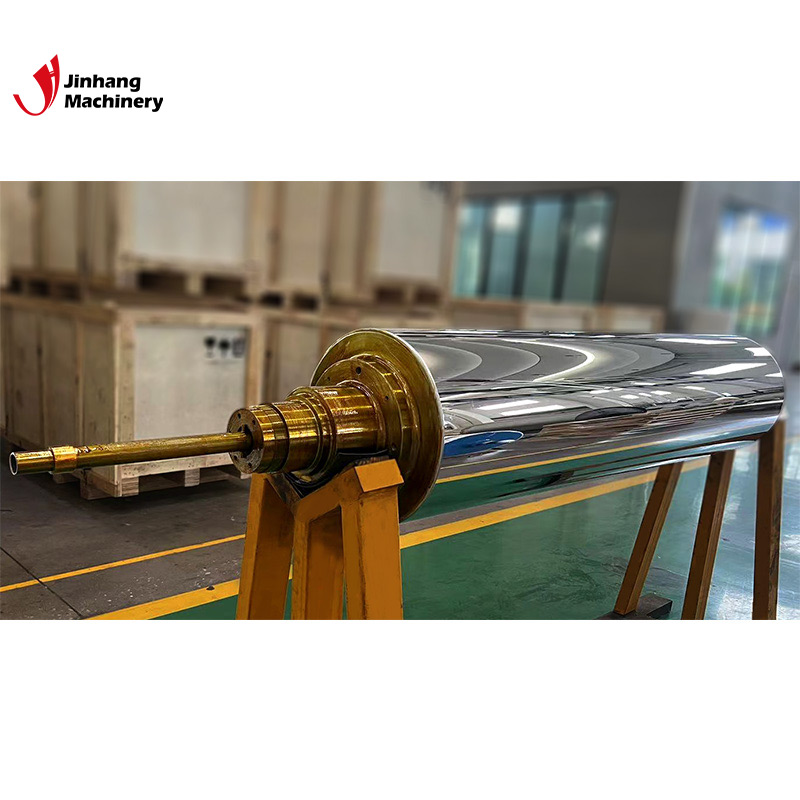

Corrosion is a major issue for industrial metal rollers, especially when they are exposed to harsh chemicals, moisture, or saltwater. Industries such as marine transportation, chemical processing, and wastewater treatment face unique challenges related to corrosion. In these environments, rollers are often exposed to aggressive substances that can rapidly degrade the material, leading to rust, pitting, and eventual failure. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. understands the critical need for corrosion-resistant solutions, and we design our industrial metal rollers with materials and coatings that are specifically engineered to resist corrosion. Stainless steel is one of the primary materials we use for corrosion-resistant rollers due to its excellent resistance to rust and oxidation. The chromium content in stainless steel allows it to form a protective oxide layer that prevents further corrosion, even in the presence of moisture or chemicals. In addition to stainless steel, we also utilize other corrosion-resistant alloys such as titanium, nickel-based alloys, and aluminum, depending on the specific needs of the application. These materials offer outstanding resistance to corrosive agents such as saltwater, sulfuric acid, and chlorides, ensuring that our rollers remain durable and reliable, even in aggressive environments. To further protect our rollers from corrosion, we apply various surface treatments such as zinc plating, epoxy coatings, and ceramic coatings. These coatings act as an additional barrier between the roller surface and corrosive substances, preventing degradation and extending the service life of the rollers. By offering a range of coatings, we can tailor the level of corrosion protection to match the severity of the environment in which the rollers will operate. We design rollers with sealed bearings and other protective features to prevent the ingress of moisture or corrosive chemicals into the internal components. This level of protection ensures that the entire roller remains operational, even in harsh, corrosive conditions.

+86-15371769898

+86-15371769898 [email protected]

[email protected]

English

English русский

русский Deutsch

Deutsch