+86-15371769898

+86-15371769898 [email protected]

[email protected]

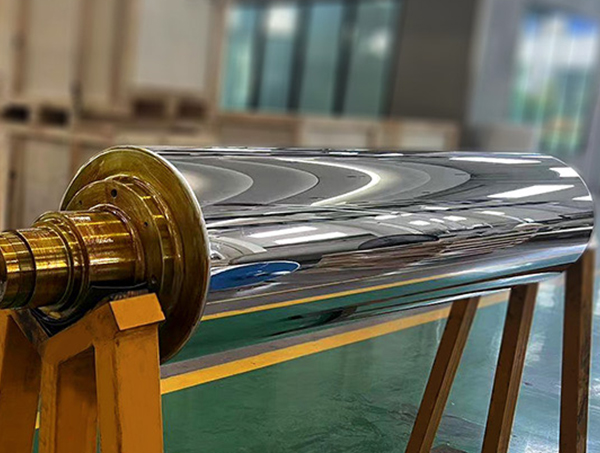

A Mirror Surface Roller is a specialized painting tool designed to produce a flawless, glossy finish on surfaces. It is widely used in both professional and DIY settings to create a smooth, high-quality coating on various surfaces like walls, furniture, automotive parts, and more.

Mirror surface rollers are distinct from standard paint rollers because they are designed specifically to apply coatings in a way that minimizes imperfections. Here are the key features that make these rollers stand out:

Mirror surface rollers are made from high-density synthetic fibers or high-quality foams. This construction helps to apply coatings evenly and prevents the roller from shedding lint or leaving streaks on the surface.

These rollers use advanced technology to ensure a smoother application. They are engineered to prevent roller lines, brush strokes, or any visible texture, resulting in a uniform, glossy finish.

Whether you’re applying high-gloss paints, varnishes, or lacquers, mirror surface rollers excel at creating the desired reflective effect. This makes them perfect for surfaces where a perfect mirror-like shine is needed.

The operation of a mirror surface roller is based on several essential factors that ensure its unique performance in creating a smooth, glossy finish.

The primary function of a mirror surface roller is its ability to apply paint or coatings evenly without leaving any visible marks or texture. This is achieved by the roller’s dense and smooth material, which helps distribute the coating thinly and evenly.

Unlike traditional rollers, which might leave visible texture or roller marks, mirror surface rollers are designed to eliminate these imperfections. The materials used in the roller’s construction help minimize the appearance of textures, resulting in an ultra-smooth, even coating.

Applying the right amount of pressure is crucial to avoid overloading the roller, which can lead to dripping or an uneven finish. Mirror surface rollers are designed to help users maintain consistent pressure throughout the application process, ensuring a uniform distribution of paint or finish.

The key to a mirror-like finish is consistent and even distribution of the coating. Mirror surface rollers are engineered with this in mind, providing a smooth application across larger surfaces. Whether you’re painting a large wall or a piece of furniture, the even coverage ensures that every inch of the surface gets an equal amount of paint.

Mirror surface rollers are most commonly used in industries where a smooth, glossy finish is essential. Here are some typical applications:

For furniture restoration projects, the mirror surface roller is ideal for applying high-gloss finishes. It helps achieve that showroom-quality shine on tables, chairs, cabinets, and other furniture pieces. It is particularly useful when restoring antique furniture, where preserving the original appearance with a glossy finish is critical.

In automotive applications, achieving a smooth, glossy paint job is a key requirement. Mirror surface rollers can be used in automotive painting to ensure that the vehicle’s surface looks professionally finished with no visible marks or texture. Whether it’s a full car repaint or detailing work, mirror surface rollers can help achieve the perfect look.

Homeowners and interior designers often use mirror surface rollers when painting walls and ceilings, especially when aiming for an upscale, luxury finish. These rollers allow you to apply a high-gloss paint without leaving texture or marks, which is ideal for achieving a polished, modern look in living rooms, bedrooms, or offices.

| Feature | Benefit |

|---|---|

| High-density fibers | Smooth, even application without lint |

| Fine finish technology | Eliminates texture and brush strokes |

| Ideal for glossy coatings | Achieves a mirror-like, high-gloss finish |

| Large coverage area | Efficient for large surfaces like walls |

| Durability | Long-lasting and resistant to wear |

To get the most out of your mirror surface roller, follow these tips:

Preparation: Ensure that the surface is clean, dry, and smooth before applying any coating. This will help the roller achieve an even finish.

Load the Roller Properly: Lightly dip the roller into the paint and roll it on a tray to evenly distribute the coating. Avoid overloading the roller.

Apply Even Pressure: Roll the paint on the surface using consistent, light pressure. This ensures that the coating is applied evenly.

Use Smooth Strokes: Apply the paint in long, continuous strokes, overlapping slightly with each pass. This technique minimizes streaks or marks.

To extend the life of your mirror surface roller and ensure it continues to provide flawless finishes, it’s important to clean and maintain it properly:

Yes, a mirror surface roller can be used on both interior and exterior surfaces. However, for exterior applications, it is recommended to use weather-resistant paints or coatings to ensure durability in outdoor conditions.

You can use high-gloss paints, varnishes, lacquers, and even certain types of clear coats with a mirror surface roller. It is best suited for coatings that require a smooth, shiny finish.

While mirror surface rollers are designed to work best on smooth surfaces, they can be used on lightly textured surfaces. However, achieving a flawless finish on heavily textured surfaces may require additional preparation and technique.

To clean the roller, rinse it thoroughly with water or a solvent appropriate for the type of coating used. If using oil-based paints, you’ll need to use a solvent like mineral spirits. Clean the roller immediately after use to prevent the paint from drying and ruining the roller fibers.

With proper care and maintenance, a mirror surface roller can last for many projects. Regular cleaning and storage will ensure its longevity and maintain its performance.