Advantages of Using Steel Rollers in Long-Term Operations

One of the most compelling reasons for choosing

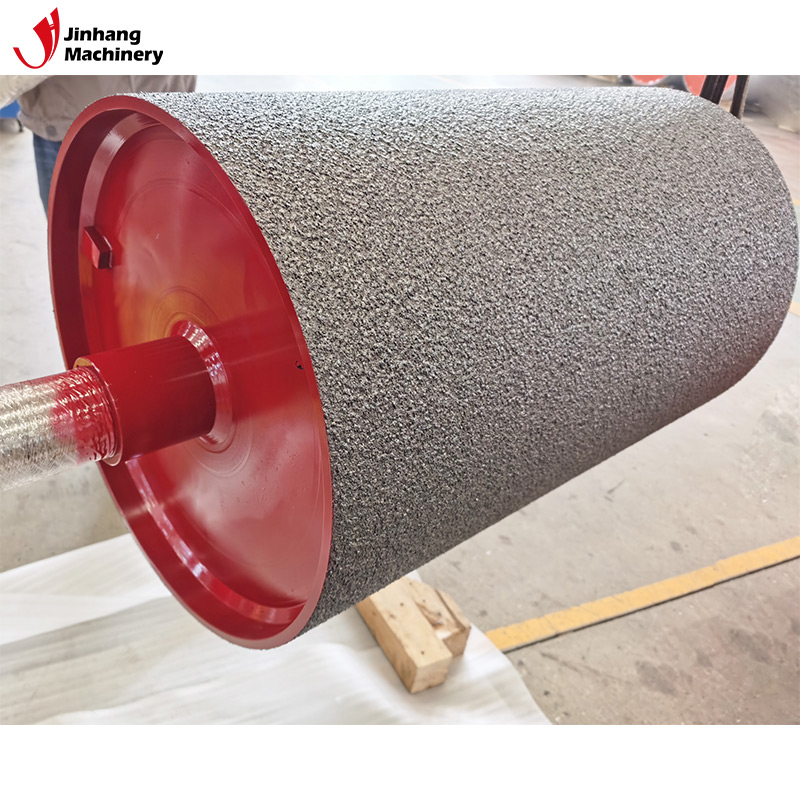

steel rollers is their exceptional durability. Steel, as a material, is known for its resistance to wear, impact, and fatigue, which makes it an ideal choice for rollers exposed to continuous use in tough environments. Steel rollers are built to last, and their strength ensures they can withstand both heavy loads and high pressures without losing shape or functionality. Over time, the initial investment in steel rollers pays off due to the reduced need for replacements and repairs. For example, in industries like mining or construction, where rollers are constantly subjected to heavy materials, the robustness of steel rollers ensures that they maintain their effectiveness over long periods. Unlike plastic or rubber rollers, which can degrade under constant stress, steel rollers retain their shape and performance, even under harsh environmental conditions. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. has developed steel rollers with superior resilience, ensuring long-lasting performance. Our products are crafted from high-quality steel materials and engineered to endure continuous use in extreme conditions, making them the perfect choice for industrial applications where durability is a must. Our commitment to rigorous quality control and ISO9001 certification guarantees that each steel roller we manufacture can withstand years of operation without compromising on performance. In the long run, the durability of steel rollers leads to fewer maintenance interventions, less downtime, and lower overall operational costs. This makes them a smarter investment for businesses looking to ensure their equipment remains operational and effective for years.

Downtime is a costly problem in any industrial operation. Every minute that a production line or construction site is idle due to malfunctioning equipment costs money, reduces productivity, and impacts project timelines. Steel rollers play a significant role in minimizing downtime by offering consistent, reliable performance even under high-stress conditions. Steel rollers are designed to operate smoothly and efficiently, regardless of the load or pressure placed upon them. Their resistance to wear and tear means that they can handle continuous operations without suffering from the type of degradation that would cause other rollers to fail. This reliability translates directly into reduced downtime. For instance, in manufacturing environments, steel rollers used in conveyor systems or metalworking machines keep operations moving smoothly without the need for constant checks or replacements. This leads to a significant increase in operational efficiency, as businesses can focus on production rather than dealing with the inconvenience of replacing rollers or dealing with mechanical failures. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. specializes in manufacturing steel rollers that reduce downtime and boost operational productivity. By ensuring our rollers maintain their functionality for an extended period, our clients can experience fewer service interruptions. In addition, the reduced frequency of maintenance checks and part replacements means that our customers spend less time on repairs, and more time focusing on what matters: efficient production and optimal performance. Steel rollers, when chosen for their durability and strength, offer a dependable solution that ensures a higher uptime for industrial machinery and systems. The consistency of performance provided by our products means that businesses can optimize their processes, reduce delays, and ultimately enhance productivity.

Although steel rollers may represent a larger initial investment compared to alternative materials, their cost-effectiveness over the long term is unparalleled. When calculating the total cost of ownership of industrial equipment, it’s essential to consider not just the upfront costs but also the long-term expenses associated with maintenance, repairs, and replacements. Steel rollers offer a clear advantage in this regard due to their durability and longevity. Many businesses make the mistake of opting for cheaper roller alternatives in an effort to reduce initial costs. However, the need for more frequent replacements and the associated downtime quickly eat into these cost savings. Steel rollers, on the other hand, provide businesses with a return on investment by minimizing these hidden expenses. With fewer replacements required and lower maintenance costs over time, steel rollers provide an excellent value proposition. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we focus on delivering high-quality steel rollers that stand the test of time. Our rollers are designed to be as cost-effective as possible, reducing the long-term operational costs for our customers. By choosing our steel rollers, businesses benefit from a product that is built to last, reducing the frequency of purchases and labor costs for maintenance. Over time, these savings accumulate, offering our clients a significant reduction in total operational costs. When you invest in our steel rollers, you're making a smart financial decision that brings about substantial savings over the lifespan of the product. The durable nature of our rollers means that businesses can operate for longer periods without the need to worry about the high costs of replacements or repairs.

Maintenance can be one of the largest ongoing expenses for any industrial operation. Regular maintenance checks, part replacements, and repairs are all necessary to ensure that machines function properly. However, this can become an expensive, time-consuming process, especially when parts degrade quickly. Steel rollers, however, minimize these issues due to their robust construction and resistance to wear. The inherent strength of steel means that our rollers can continue to perform without showing signs of fatigue, even after extended use. They do not require constant monitoring for issues such as cracking, bending, or surface damage, which is common in alternative materials. In addition, steel rollers are less prone to degradation from exposure to harsh chemicals, UV rays, or extreme temperatures, all of which can cause other materials to break down prematurely. This resistance to wear significantly reduces the need for regular inspections, replacements, and repairs. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we prioritize the manufacturing of steel rollers that require minimal maintenance. The rollers we produce are engineered for longevity, which means fewer maintenance interventions and fewer replacements needed throughout their operational life. Our customers enjoy a more streamlined approach to maintenance, allowing them to allocate their resources more efficiently and avoid the operational disruptions associated with unexpected downtime. The long life span and reliable performance of our steel rollers mean that our clients experience less inconvenience and reduced operational costs. This translates into fewer parts needing to be replaced and less overall maintenance required, all contributing to more predictable and cost-effective operations.

Many industries face extreme operational conditions that place significant demands on their equipment. Whether in high temperatures, corrosive environments, or environments with heavy pressure and loads, industrial machinery must be able to withstand these challenges to continue functioning effectively. Steel rollers excel in these harsh environments, offering superior performance that other materials simply cannot match. Steel is an inherently strong material that can handle heavy loads and pressure without warping or losing its functionality. In applications such as mining, heavy construction, and manufacturing, steel rollers are used in machinery that must endure exposure to abrasive materials, extreme heat, or corrosive substances. Unlike rubber or plastic rollers, which degrade quickly under these conditions, steel rollers retain their performance over time, providing a reliable solution in industries where environmental factors are an ongoing concern. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. has spent years refining steel roller designs that offer outstanding performance in the most challenging environments. Our steel rollers are manufactured to meet the specific needs of industries dealing with abrasive, corrosive, or high-pressure conditions. By using high-quality steel, we ensure that our rollers maintain their strength and functionality despite exposure to demanding environments. For industries that operate in extreme conditions, the superior performance of our steel rollers provides a competitive edge, ensuring that machinery remains efficient and reliable, no matter how harsh the operating environment may be.

Steel rollers are known for their ability to maintain consistent performance throughout their operational life. This is crucial in industries that require a high degree of precision and regularity, such as printing, packaging, and material handling. The ability of steel rollers to maintain their structural integrity ensures that the machines they are integrated into continue to perform with accuracy and consistency, even after years of use. In industries like printing, consistency is key to ensuring high-quality output. Steel rollers ensure that pressure is applied evenly, and materials are moved smoothly through the system. The consistent performance of steel rollers minimizes the risk of defects or inconsistencies in the final product. In material handling systems, steel rollers maintain their functionality over time, ensuring that items are transported efficiently without jamming or slipping. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. prides itself on producing steel rollers that offer consistent performance, whether for delicate tasks or heavy-duty applications. We understand that industries require rollers that can meet their specific needs, which is why our rollers are engineered to provide the precision and reliability required for long-term use. By investing in our steel rollers, industries can maintain high levels of productivity and quality without the worry of performance degradation over time.

+86-15371769898

+86-15371769898 [email protected]

[email protected]

English

English русский

русский Deutsch

Deutsch