The Role of Mirror Surface Rollers in Calendering Processes

The calendering process is fundamental in transforming raw materials into finished products with specific properties, primarily focusing on thickness control, smoothness, and uniformity. During calendering, materials are passed between rollers under controlled heat and pressure, shaping them into a consistent sheet or film. This process is crucial for materials that require a smooth, polished surface or a precise thickness, such as plastic films, leather, textiles, and paper. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we manufacture mirror surface rollers that play a pivotal role in achieving these desired material characteristics. Our rollers are designed to maintain high levels of uniformity, ensuring the calendered material meets strict quality standards in industries such as automotive manufacturing, packaging, textiles, and synthetic leather production. Calendering provides various benefits, including the ability to adjust thickness, density, and surface texture to meet specific product requirements. For example, the calendering process enables us to produce plastic films with uniform thickness, ensuring that the material is suitable for high-performance applications such as electronic components and packaging. The high precision provided by our mirror surface rollers ensures that the material passes through the rollers with minimal deformation or defects, achieving the exact properties required by the end product. This precision is essential for the success of industries that demand stringent specifications, such as electronics or automotive applications. Therefore, the role of mirror surface rollers is indispensable in maintaining the integrity of the final material.

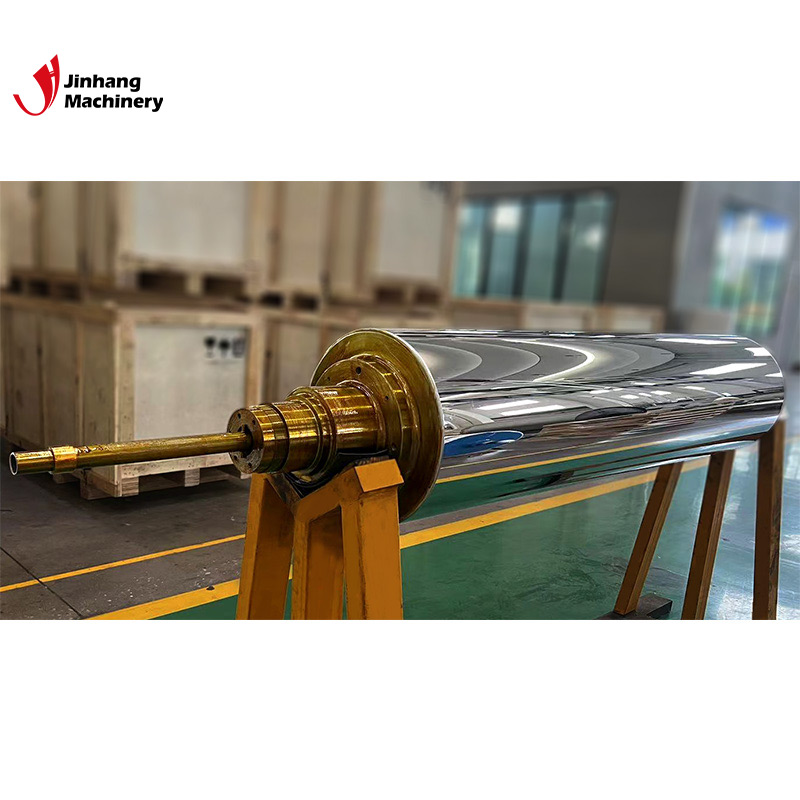

Mirror surface rollers are designed to achieve smooth and glossy finishes on a wide range of materials. These rollers are particularly essential in applications where surface quality is of utmost importance, such as the production of films, textiles, and artificial leather. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we take great care to craft our rollers with the precision and attention to detail required to meet the highest surface quality standards. The highly polished surface of our mirror rollers provides a smooth and reflective finish, which is crucial for materials like PVC, PE, PT, and PC plastics. These materials often require smoothness and shine for aesthetic appeal, as well as for functional properties such as ease of handling, sealing, and durability. For instance, in the production of automotive interiors, the glossy finish provided by our mirror surface rollers is vital in producing high-end plastic components that require an immaculate surface finish. In addition to plastics, mirror surface rollers are also used extensively in the leather and textile industries, where the surface texture plays a key role in the appearance and feel of the final product. Whether it's synthetic leather or upholstery fabrics, mirror surface rollers help produce a uniform, shiny surface that enhances the overall quality of the material. Our expertise in customizing roller specifications allows us to cater to different material types, adjusting the pressure and heat distribution to achieve the desired surface characteristics without compromising the integrity of the material.

Every industry and application has unique requirements, and at Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we offer highly customizable mirror surface rollers to meet these diverse needs. We understand that different materials and manufacturing processes require specific roller characteristics, including the level of smoothness, surface texture, and material hardness. To accommodate these needs, we offer tailored roller designs based on client specifications. Customization can range from the size and shape of the roller to the material used for the roller's construction and the coatings applied to the surface. For example, in the production of thin plastic films, rollers with specific surface treatments are essential to prevent material sticking or warping. Conversely, for calendering heavier materials, such as leather or thick textiles, we provide rollers with enhanced structural integrity to ensure consistent performance under higher loads and temperatures. The ability to tailor our rollers ensures that our customers receive the most effective solution for their unique manufacturing challenges. By collaborating closely with clients, we design rollers that meet their specific operational requirements, whether that involves modifying the surface finish, adjusting the roller's diameter, or incorporating specialized coatings for increased wear resistance or enhanced chemical properties. Our custom-made rollers not only improve the quality of the final product but also help optimize production processes, reducing downtime and improving efficiency.

The durability of a roller plays a significant role in the overall performance and longevity of the calendering process. To ensure that our mirror surface rollers meet the demands of high-volume production, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. applies advanced coatings and surface treatments to increase the lifespan and resilience of the rollers. These coatings serve multiple functions, including improving resistance to wear, corrosion, and thermal degradation, as well as enhancing the chemical properties of the roller's surface. One of the most common coatings we apply is chrome plating, which provides excellent wear resistance and a smooth, non-porous surface. Chrome plating is particularly useful in industries where rollers are exposed to harsh conditions, such as the processing of plastics or metals. In these applications, the high temperature and friction can cause the roller surface to degrade over time, but chrome plating ensures that the rollers retain their smoothness and structural integrity even under heavy use. For industries that require even more durability, such as when processing high-performance polymers or metals, we also offer tungsten carbide and ceramic coatings. Tungsten carbide coatings significantly increase the hardness of the roller surface, making it highly resistant to wear and ideal for high-pressure applications. Ceramic coatings, on the other hand, offer excellent resistance to corrosion and are often used when processing materials that are chemically reactive or require a high degree of thermal stability. These coatings enhance the performance of our mirror surface rollers and extend their service life, making them suitable for a wide range of demanding industrial applications.

In the calendering process, achieving precise material control is crucial for producing high-quality finished products. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. understands that controlling the thickness and surface smoothness of the material is essential for industries that require precise specifications. Our mirror surface rollers play a significant role in ensuring that materials are processed with exactness, minimizing inconsistencies in thickness and surface texture. When working with materials like PVC, PE, and PT plastics, even slight variations in thickness can result in product defects or performance issues in the final application. For example, in the packaging industry, uneven film thickness can lead to issues such as poor sealing or inadequate strength. To mitigate this, our mirror surface rollers ensure uniform pressure distribution, which guarantees a consistent thickness throughout the calendering process. Similarly, when processing textiles, paper, or leather, we focus on achieving smoothness and uniform texture to meet quality standards. Our advanced design techniques ensure that the rollers distribute heat evenly and apply consistent pressure, preventing surface defects such as wrinkles, streaks, or uneven gloss. By maintaining precise control over these factors, we help ensure that the final product meets both aesthetic and functional requirements.

The ability to precisely control the temperature during the calendering process is one of the most critical factors in achieving high-quality results. Many materials, particularly plastics and rubber, need to be heated to a specific temperature to reach the desired level of softness and malleability. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. incorporates advanced heating structures in our mirror surface rollers to ensure that temperature control is consistent and reliable. Our heating systems are designed to distribute heat evenly across the roller’s surface, allowing the material to pass through the rollers at a uniform temperature. This prevents issues such as uneven processing or temperature gradients, which could lead to defects in the material. The controlled heating environment helps improve the material flow and reduces the likelihood of the material sticking to the roller surface, ensuring that the calendering process remains smooth and uninterrupted. Temperature control also plays a vital role in the formation of metallic coatings on materials, such as when creating shiny metal finishes on plastics or films. With our precisely engineered heating structures, we can help our clients achieve consistent and rich metallic finishes that are often required in the automotive and packaging industries. The ability to control heat levels enables us to process a wider variety of materials efficiently, ensuring that our rollers can handle both high-temperature and low-temperature operations as needed.

In any manufacturing process, efficiency is a key factor that directly impacts productivity and profitability. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. recognizes the importance of minimizing downtime and ensuring smooth operations throughout the calendering process. Our mirror surface rollers are specifically designed to reduce the likelihood of defects or malfunctions, which can lead to costly delays and increased maintenance requirements. The durability and precision of our rollers ensure that the calendering process remains stable and consistent, reducing the need for frequent adjustments or repairs. Our high-quality coatings, customized designs, and reliable heating systems contribute to a more efficient process, allowing for faster production cycles and higher throughput. By reducing the risk of downtime, our rollers help improve the overall efficiency of the calendering operation, leading to greater cost savings and better utilization of production resources. The smooth surface of our rollers prevents material buildup, which can often cause production halts and the need for cleaning or maintenance. With Jiangsu Jinhang Machinery Manufacturing Co., Ltd.'s mirror surface rollers, companies can achieve longer operational lifespans and maintain consistent quality with less frequent interruptions, ultimately boosting overall productivity.

+86-15371769898

+86-15371769898 [email protected]

[email protected]

English

English русский

русский Deutsch

Deutsch