Key Features and Benefits of Hard Alloy Coated Rollers

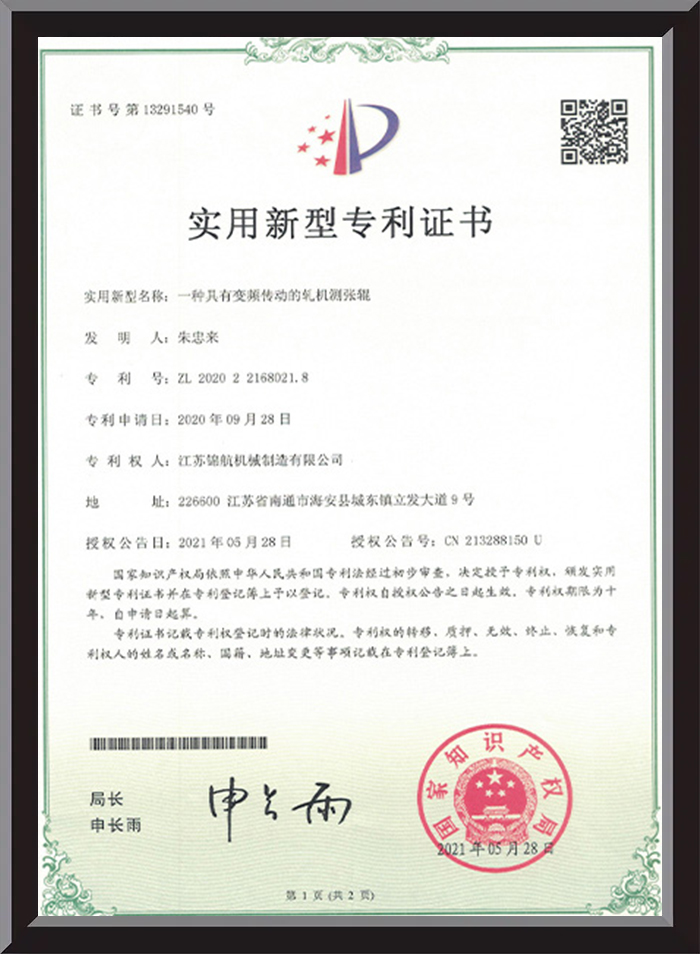

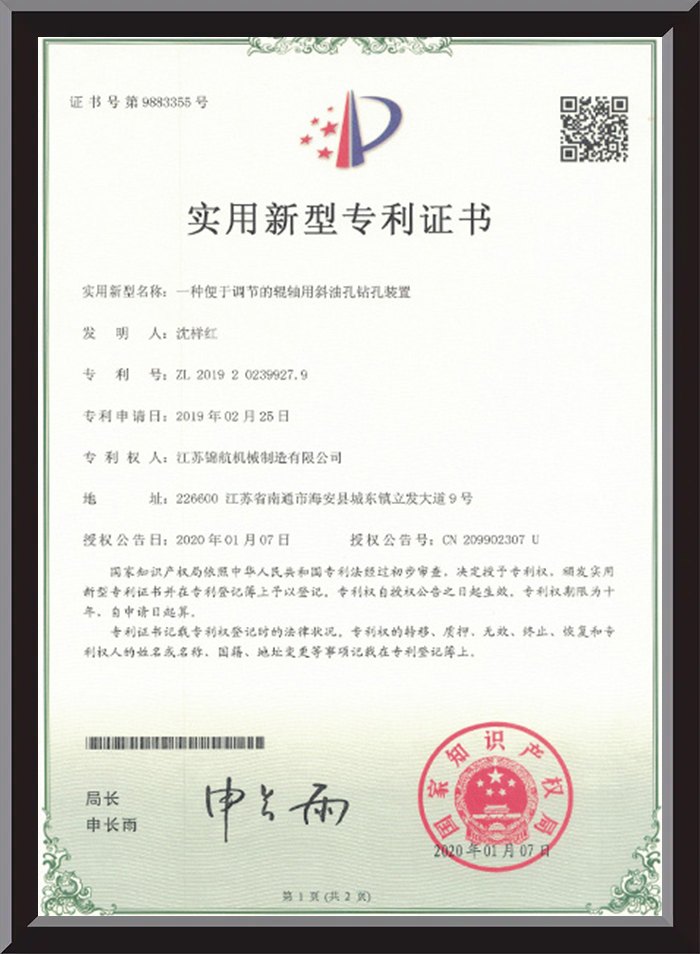

Hard alloy coated rollers offer superior wear resistance, one of their most significant advantages in industrial applications. In the harsh conditions of manufacturing and material handling, conventional rollers often wear out quickly due to continuous friction and abrasive contact with materials. Our hard alloy coated rollers, developed and manufactured by Jiangsu Jinhang Machinery Manufacturing Co., Ltd., are engineered to withstand such conditions for extended periods. The wear resistance of these rollers comes from the high hardness of the alloy coating, which prevents surface damage from abrasive particles, reducing surface degradation over time. For industries like mining and metal processing, where equipment is subjected to abrasive dust, rocks, or heavy materials, this feature becomes essential. The enhanced hardness ensures that the rollers maintain their structural integrity, even under harsh conditions, which would quickly wear out traditional materials. Wear resistance leads to reduced maintenance needs. Since the rollers last longer, industries can avoid the frequent downtime required for replacing worn-out rollers, contributing to operational efficiency. For companies relying on large-scale operations with continuous or heavy-duty machinery, such as those in the manufacturing or logistics industries, our hard alloy coated rollers help keep their systems running smoothly for longer periods, thereby reducing operational costs. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we focus on optimizing our hard alloy coating technology to offer the highest level of wear resistance. This innovation ensures that our rollers provide exceptional durability, which helps businesses maintain steady production rates, reduce maintenance-related expenses, and improve overall equipment lifespan.

In industries dealing with extreme heat conditions—such as steel production, automotive manufacturing, or chemical processing—heat resistance is a critical factor in maintaining roller performance. Traditional rollers made of standard materials often degrade or lose functionality when exposed to high temperatures. Our hard alloy coated rollers, produced by Jiangsu Jinhang Machinery Manufacturing Co., Ltd., are designed to endure such conditions without experiencing the common failures associated with heat, such as warping, cracking, or material fatigue. The alloy coating applied to our rollers enhances their ability to perform under extreme temperatures. This process significantly raises the thermal resistance of the rollers, ensuring that they can withstand thermal shock and prolonged exposure to heat. As industries such as steel manufacturing or cement production subject rollers to high heat during operations, this characteristic proves invaluable. The enhanced thermal stability also reduces the likelihood of material degradation, ensuring the longevity of the roller even when exposed to temperatures that would quickly damage ordinary rollers. By incorporating advanced alloy materials, our rollers can maintain their operational efficiency even at elevated temperatures, ensuring that high-performance standards are upheld. This is particularly important in industries where precision and continuous operation are critical, and any downtime can have serious financial implications. By using our hard alloy coated rollers, companies can avoid the need for frequent roller replacements and costly repairs, which would be inevitable with inferior products. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., our commitment to thermal resistance allows us to offer rollers that support the safe and efficient operation of machinery in high-temperature environments, contributing to improved overall productivity and reduced maintenance costs.

In industrial applications, particularly in heavy-duty sectors such as mining, construction, and materials handling, the rollers used are required to bear substantial loads. Hard alloy coated rollers stand out in this area due to their superior load-bearing capacity, a feature that is vital for industries dealing with heavy machinery and materials. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., our rollers are designed to handle substantial weight and pressure without compromising their integrity, ensuring reliability even under extreme conditions. The hard alloy coating not only strengthens the surface of the roller but also enhances its internal structure, allowing the roller to absorb and distribute the load more efficiently. This makes our rollers ideal for applications such as conveyor systems that transport heavy goods or in mining operations where rollers are subjected to constant weight-bearing stresses. Unlike traditional rollers, which may deform or wear out when exposed to these high loads, our hard alloy coated rollers maintain their shape and functionality over an extended period. High load-bearing capacity is essential for maintaining the safety and efficiency of industrial operations. Rollers that fail under heavy loads can cause production halts, equipment damage, and operational hazards. Our rollers provide enhanced safety and reliability by maintaining consistent performance, even in challenging applications. The ability to withstand high loads without failure directly impacts the efficiency and safety of manufacturing systems, reducing the risk of catastrophic breakdowns or downtime. By providing custom load-bearing solutions, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. helps industries maintain smooth and efficient operations, minimizing interruptions and maximizing productivity. Our expertise in designing rollers that can handle varying levels of pressure ensures that businesses can achieve greater operational efficiency.

One of the most impactful benefits of hard alloy coated rollers is their ability to reduce friction. Friction is an inevitable part of many industrial processes, especially in equipment such as conveyor belts, rollers, and machinery that require smooth operation. Conventional rollers with higher friction can lead to increased energy consumption, as more power is needed to overcome the resistance during operation. Our hard alloy coated rollers, developed by Jiangsu Jinhang Machinery Manufacturing Co., Ltd., are engineered to minimize friction, offering a solution that helps businesses reduce energy costs. The advanced alloy coating on our rollers provides a smoother surface that reduces rolling resistance, which is crucial for industries that rely on high-efficiency systems. By minimizing friction, these rollers require less power to perform the same task, translating into reduced energy consumption and lower operational costs. For large-scale operations that rely on conveyor systems or machinery that runs continuously, the energy savings can be substantial. Over time, this leads to a significant reduction in electricity costs, contributing to a more cost-effective operation. Lower friction results in less wear and tear on the roller and other components of the machinery, which reduces the need for frequent maintenance. The reduction in friction also improves the overall performance and longevity of the equipment, ensuring that operations run smoothly and efficiently with less downtime. By choosing our hard alloy coated rollers, businesses benefit from both direct cost savings and a more reliable, energy-efficient operational system. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. takes pride in our ability to deliver roller solutions that not only perform well under demanding conditions but also promote sustainability and energy efficiency. Our commitment to reducing friction in industrial applications is part of our larger goal to support businesses in achieving operational excellence.

Corrosion is a common issue in industries where rollers are exposed to moisture, chemicals, and harsh environmental conditions. Rollers made of traditional materials are often vulnerable to rust and degradation, which can severely shorten their lifespan and increase the frequency of replacement. Our hard alloy coated rollers, engineered by Jiangsu Jinhang Machinery Manufacturing Co., Ltd., offer superior corrosion resistance, which significantly extends their operational life. The specialized hard alloy coating forms a protective barrier on the roller surface, preventing corrosion from occurring even in environments where conventional rollers would quickly degrade. This feature is particularly important for industries such as mining, chemical processing, and maritime operations, where equipment is regularly exposed to corrosive elements like water, chemicals, or salt. The enhanced corrosion resistance of our rollers allows them to maintain optimal performance and appearance even when exposed to these harsh conditions. By reducing the risk of corrosion, our rollers help businesses avoid costly repairs and downtime. Corrosion not only weakens the structure of the roller but can also lead to equipment failures, safety hazards, and unplanned maintenance. With our corrosion-resistant rollers, businesses can rely on consistent performance and minimize the need for frequent replacements or repairs. This makes our hard alloy coated rollers a reliable and cost-effective solution for industries that face environmental challenges. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. ensures that all our hard alloy coated rollers are designed to withstand the elements and perform reliably over the long term. Our expertise in corrosion-resistant coatings guarantees that our rollers offer exceptional longevity, contributing to better overall reliability and cost savings for our customers.

At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we understand that each industrial application has unique requirements. Our hard alloy coated rollers are fully customizable to meet the specific needs of our customers. Whether it's the size, shape, load-bearing capacity, or coating thickness, we work closely with clients to design and manufacture rollers that meet their exact specifications. This flexibility ensures that we can deliver roller solutions that are optimized for the demands of different industries. Customization is particularly valuable in industries where standard roller solutions may not be sufficient. For example, in industries like food processing or pharmaceuticals, where precision and cleanliness are critical, we can create rollers with specific features that adhere to hygiene standards. For industries dealing with extreme conditions, such as high pressures or corrosive chemicals, we can tailor the hard alloy coating to provide additional protection where it is most needed. By offering custom solutions, we ensure that our rollers are fully aligned with our customers' operational needs. This not only enhances performance but also reduces the need for adjustments or modifications after installation. With our custom roller solutions, businesses can enjoy improved efficiency, reduced downtime, and long-term reliability. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. excels at providing tailored roller solutions that meet the unique challenges of our customers, ensuring that each roller delivers the best possible performance in its intended environment.

+86-15371769898

+86-15371769898 [email protected]

[email protected]

English

English русский

русский Deutsch

Deutsch