Applications of Carbon Steel Rollers in Industrial Systems

In the metallurgical industry,

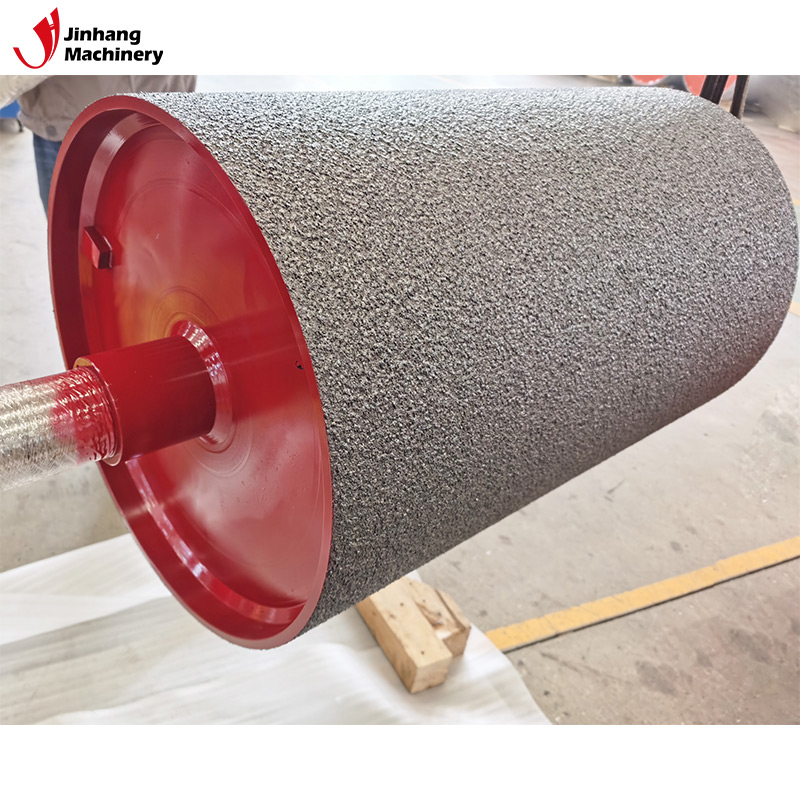

carbon steel rollers are used in various critical processes, particularly in rolling mills, where their mechanical properties are put to the test. Our carbon steel rollers are designed to support high loads and operate in extremely high-temperature environments. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we understand the importance of durability and precision in metallurgy, where the physical demands on rollers are among the highest in any industry.

Hot and Cold Rolling Mills: In both hot and cold rolling mills, carbon steel rollers facilitate the movement of metal billets or slabs through various stages of rolling. For hot rolling, where metals are heated to high temperatures before being passed through rollers to reduce thickness, our rollers are designed to withstand extreme heat and mechanical stress. Our carbon steel rollers maintain dimensional stability even in high-temperature conditions, which ensures the metal sheets or plates being processed are of consistent quality. In cold rolling, our rollers assist in reducing the thickness of metal at ambient temperatures, offering high surface finish and mechanical properties without compromising strength.

Forging and Extrusion: In forging operations, carbon steel rollers are used to support and transport forged products, including structural beams, shafts, and rods, through various machinery. These rollers must be robust enough to handle the substantial mechanical forces generated during the forging process. Similarly, in extrusion processes, where metals like aluminum or copper are forced through dies to create long sections of material, our carbon steel rollers play a crucial role in guiding and moving these extruded materials. The rollers help maintain the precision and consistency required in creating extrusions used in automotive, aerospace, and construction industries.

By using our high-quality carbon steel rollers, metallurgical plants benefit from enhanced reliability and efficiency in metal processing operations. With years of expertise in the manufacturing of specialized rollers, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. ensures that each roller is engineered to meet the stringent demands of the industry.

The machinery manufacturing sector demands components that can withstand high operational demands while ensuring precision. Carbon steel rollers are integral to the seamless functioning of various automated machinery and conveyor systems used in manufacturing plants. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we have designed our carbon steel rollers to be particularly durable and capable of operating in high-stress environments, ensuring smooth material handling across diverse applications.

Conveyor Systems: In machinery manufacturing, conveyors are essential for moving raw materials, components, and finished products along production lines. Carbon steel rollers are used in these conveyor systems to facilitate smooth movement while bearing heavy loads. These rollers ensure that production processes are continuous and efficient, reducing downtime and mechanical failures. Our carbon steel rollers are designed to operate under constant stress, offering high wear resistance and minimal maintenance, even when exposed to abrasive or heavy materials. We ensure our rollers are tailored to the exact dimensions and specifications of each system, enhancing the performance of the conveyor systems they are part of.

Robotic and Automated Assembly Lines: In automated manufacturing plants, robots and machines move parts through assembly lines, performing tasks such as welding, screwing, or painting. Our carbon steel rollers are integrated into these automated systems to ensure parts move smoothly between stations. These rollers are essential for maintaining the efficiency of the assembly line, ensuring that each part is accurately positioned and transported at the correct speed. By minimizing the chances of mechanical failure, our rollers contribute to the high productivity and precision required in modern automated manufacturing.

At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we understand the importance of reliability and efficiency in machinery manufacturing, and we ensure our carbon steel rollers meet these exacting standards.

The papermaking and printing industries have highly specific needs when it comes to the equipment used in their production processes. Carbon steel rollers are essential in moving paper pulp, drying paper, and handling printed materials. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we provide rollers specifically designed to handle the conditions unique to the papermaking and printing industries, such as high moisture levels and high-speed production demands.

Papermaking Machines: In the papermaking industry, carbon steel rollers are used in various stages of the production process, from pressing and dewatering the pulp to drying the paper. These rollers help remove excess water from the pulp, guiding it through the press section, and are also used to dry the paper at high temperatures. Our carbon steel rollers are designed to resist corrosion caused by constant exposure to moisture and chemicals, while also maintaining structural integrity under the pressure and temperature conditions found in papermaking machines. With our rollers, manufacturers benefit from improved productivity, reduced maintenance costs, and extended equipment lifespans.

Printing Presses: Carbon steel rollers are integral to offset printing presses, where they ensure the even distribution of ink onto paper or other materials. The rollers help control the flow of ink, providing precise coverage for high-quality prints. In the printing industry, where speed and accuracy are critical, the durability of our carbon steel rollers ensures smooth operation of the printing press, even under continuous, high-speed conditions. We also design rollers for the feeding and delivery mechanisms of printing presses, ensuring that materials are handled delicately and efficiently, preventing jams and ensuring high print quality throughout long production runs.

Through our commitment to precision and quality, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. provides carbon steel rollers that enhance both the operational efficiency and output quality of papermaking and printing facilities.

The textile industry relies heavily on the functionality of rollers in multiple stages of production, from weaving to dyeing. Carbon steel rollers are used to move materials through machinery while ensuring fabric quality is not compromised. Jiangsu Jinhang Machinery Manufacturing Co., Ltd. designs rollers that meet the unique needs of textile manufacturers, including the ability to resist the wear and tear caused by exposure to chemicals, heat, and abrasive materials.

Weaving and Knitting Looms: In textile manufacturing, looms use rollers to guide and control yarns during the weaving or knitting process. The rollers must maintain consistent tension on the yarns, preventing breakage and ensuring uniform fabric production. Our carbon steel rollers are engineered for precise movement, which ensures that fabric production remains smooth and uninterrupted. We design our rollers to be strong enough to withstand the stresses involved in yarn handling while also being resistant to abrasion from the yarns themselves.

Dyeing and Finishing: The dyeing and finishing processes involve large machines that treat fabrics with chemicals or dyes. Carbon steel rollers are used in dyeing machines to move textiles through liquid baths while maintaining constant pressure and speed. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we offer rollers that are specially coated or treated to prevent corrosion caused by the chemicals used in these processes. Additionally, our rollers are designed to ensure that fabrics are treated evenly, allowing for consistent color and texture in the final product.

Through our durable and specialized carbon steel rollers, we help textile manufacturers improve production efficiency and product quality, while also extending the lifespan of their equipment.

In the food processing industry, hygiene is a top priority, and carbon steel rollers are used to move products through various stages of processing, packaging, and storage. At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we understand the rigorous sanitation standards required in food processing. Our carbon steel rollers are designed to meet these standards while ensuring operational efficiency and durability.

Conveying Food Products: In food processing plants, carbon steel rollers are used in conveyors to transport raw ingredients, such as fruits, vegetables, and meat, through different stages of processing. These rollers must be resistant to food particles, moisture, and temperature changes to ensure that they do not become contaminated. We design our carbon steel rollers with food-grade coatings and finishes that are easy to clean and maintain, ensuring that food safety standards are met at all times.

Packaging and Sorting: After food products are processed, they need to be packaged and sorted for distribution. Our carbon steel rollers are used in the packaging lines to move finished products from one station to another. Whether it is boxed goods or bottled beverages, our rollers ensure the smooth movement of products to reduce delays and improve packaging efficiency. By offering rollers that are both durable and easy to clean, we help food manufacturers meet both productivity and hygiene standards.

At Jiangsu Jinhang Machinery Manufacturing Co., Ltd., we ensure that our carbon steel rollers provide consistent, reliable performance in food processing, helping companies meet both production targets and regulatory requirements.

In the chemical and pharmaceutical industries, where precision and reliability are critical, carbon steel rollers are used in various equipment to transport raw materials, intermediate products, and finished goods. The harsh conditions of chemical plants and pharmaceutical manufacturing require rollers that can withstand chemical exposure, extreme temperatures, and high mechanical stress. Our carbon steel rollers are designed with these requirements in mind, ensuring optimal performance in these demanding environments.

Chemical Processing Equipment: In chemical plants, carbon steel rollers are used in conveyors, mixers, and reactors to handle raw chemicals or processed materials. These environments often involve exposure to corrosive substances, so our rollers are designed with corrosion-resistant coatings or surface treatments to extend their lifespan. The rollers help move materials through various stages of processing, ensuring that there are no disruptions to production due to equipment failure. We also engineer our rollers to handle high loads and operate smoothly at high speeds.

Pharmaceutical Manufacturing: In pharmaceutical production, precision is critical, and carbon steel rollers are used in systems that handle everything from raw ingredients to finished medications. These rollers are used in tablet presses, coating machines, and packaging lines, where they provide reliable support and transportation of materials. Our carbon steel rollers are designed to meet the stringent cleanliness and performance standards required in pharmaceutical manufacturing, ensuring that products are produced efficiently and safely.

Jiangsu Jinhang Machinery Manufacturing Co., Ltd. manufactures carbon steel rollers that meet the high standards demanded by the chemical and pharmaceutical industries, ensuring reliable and efficient operations.

+86-15371769898

+86-15371769898 [email protected]

[email protected]

English

English русский

русский Deutsch

Deutsch