Benefits of Using the Oil-Conductive Heating Roller in Industrial Manufacturing

The

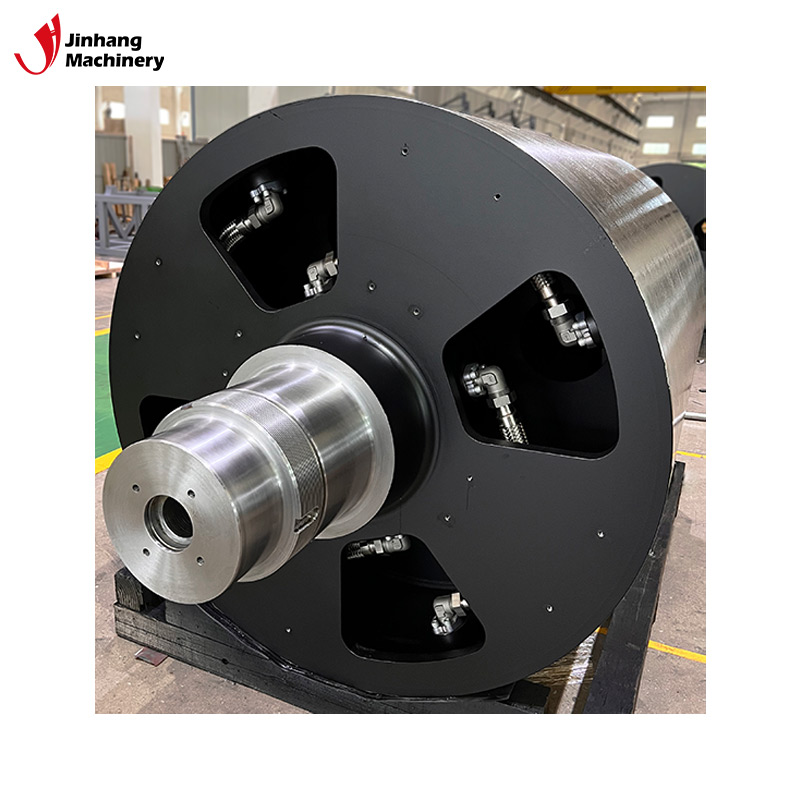

Oil-Conductive Heating Roller offers significant benefits in terms of heat distribution and temperature uniformity. Heat consistency is crucial in industrial manufacturing processes, especially when producing high-quality materials that require precise processing conditions. Unlike traditional electric or steam heating methods, the Oil-Conductive Heating Roller integrates oil circulation directly within the roller body, ensuring even heat distribution. This feature allows for consistent surface temperatures, reducing the likelihood of hot spots or temperature fluctuations that could compromise the quality of our products. For Jiangsu Jinhang Machinery Manufacturing Co., Ltd., providing such precision in heat distribution enables us to offer custom-designed rollers tailored to meet the specific requirements of industries such as plastics, textiles, and metal processing. In these sectors, even slight temperature imbalances can lead to defects like warping, uneven thickness, or poor surface texture, resulting in product waste and decreased efficiency. With the Oil-Conductive Heating Roller, we benefit from improved consistency throughout the production cycle. The oil circulation system ensures that the entire roller surface maintains an optimal and uniform temperature, thereby improving the overall performance and consistency of the material being processed. For example, in the calendering process of PVC films, a uniform temperature distribution prevents issues like inconsistent film thickness, resulting in higher quality products with better mechanical properties. This uniformity also leads to a more efficient production process, as we can run longer production cycles without worrying about temperature-induced defects or material failures. This technology significantly enhances our ability to produce high-quality materials consistently. For Jiangsu Jinhang Machinery Manufacturing Co., Ltd., this advantage translates into increased customer satisfaction and fewer production interruptions, helping us maintain a competitive edge in the market.

Another major advantage of the Oil-Conductive Heating Roller is the enhanced process control and precision it offers. In manufacturing processes, especially those that involve the processing of sensitive or high-performance materials, temperature control is critical. The ability to adjust and maintain a specific temperature profile within a narrow range can be the difference between a high-quality product and a defective one. Traditional heating methods, like steam or electrical resistance heating, may struggle with providing such fine control, often resulting in temperature variations that affect the material quality. For Jiangsu Jinhang Machinery Manufacturing Co., Ltd., this precise control is a game-changer, especially when designing custom rollers for different applications. By integrating oil as the heat transfer medium, we can offer a more responsive and adaptable heating system that meets the specific temperature requirements of different materials. This capability is particularly useful when working with materials like thermoplastics, elastomers, or composite materials, which require precise thermal profiles to ensure proper processing. For example, when manufacturing plastic films or synthetic leather, any deviation from the desired temperature can result in poor adhesion, uneven surface textures, or even material failure. The Oil-Conductive Heating Roller enables us to achieve the precision required to avoid such issues. With the ability to fine-tune the roller’s heating system, we can set specific temperature parameters based on the material’s requirements, ensuring the material undergoes a uniform and controlled processing cycle. This is especially beneficial in industries that require exact specifications for product performance, such as automotive manufacturing or electronics. With precise process control, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. ensures that our rollers consistently produce high-quality, defect-free materials, improving both product quality and operational efficiency.

Energy consumption is one of the largest operating expenses in manufacturing facilities. As industries increasingly prioritize energy savings and cost reduction, the Oil-Conductive Heating Roller provides a more energy-efficient solution compared to traditional heating systems. Unlike steam-based systems or electric resistance heaters, which often generate significant amounts of wasted heat or require high levels of power to reach the desired temperature, oil-conductive systems optimize heat transfer, reducing energy consumption in the process. For Jiangsu Jinhang Machinery Manufacturing Co., Ltd., the ability to offer energy-efficient rollers helps us provide a more sustainable solution to our clients. The oil circulating through the roller body serves as an efficient heat transfer medium, allowing for faster heat up times and more effective temperature regulation. Once the desired temperature is reached, the oil’s high thermal capacity ensures that heat is retained longer, reducing the need for continuous energy input. This leads to lower electricity consumption and less wear on heating components. This improved energy efficiency leads to a reduction in operational costs. For manufacturers who operate at scale, such as those producing large quantities of plastic sheets or synthetic materials, even modest reductions in energy use can result in significant savings. By reducing the overall energy required to operate roller system, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. helps our customers lower their production costs, making our products more appealing in terms of both quality and cost-effectiveness. Oil-based systems are typically more reliable than traditional electrical or steam heating, as they are less prone to fluctuations or failures. This reliability further contributes to the reduction of downtime, allowing for smoother and more efficient production runs. For us, offering energy-efficient solutions through the Oil-Conductive Heating Roller not only helps reduce costs but also supports our commitment to sustainability.

The durability of manufacturing equipment is always a priority, as frequent breakdowns and maintenance can lead to increased operational downtime and reduced production efficiency. Traditional heating methods often cause localized thermal stresses on the roller body, which can lead to material degradation over time. These stresses result in cracks, warping, or other types of wear that require costly repairs or replacement. In contrast, the Oil-Conductive Heating Roller offers a more stable thermal environment. By using oil as the heat transfer medium, the roller experiences more uniform heat distribution, which minimizes thermal stresses. This leads to reduced wear on the roller surface and helps maintain the structural integrity of the roller over time. For Jiangsu Jinhang Machinery Manufacturing Co., Ltd., this durability is a key selling point when designing custom rollers for our customers. The oil-based heating system also reduces the likelihood of component failure due to overheating, as the oil circulates continuously, preventing the roller from reaching temperatures that might cause damage. This contributes to a longer lifespan for the roller, minimizing the need for frequent repairs or replacements. For us, this is a significant advantage, as it reduces maintenance costs and helps our customers achieve more consistent production cycles. The increased lifespan of the Oil-Conductive Heating Roller means less material waste over the course of its use, aligning with broader industry goals of sustainability. By minimizing the frequency of equipment replacements, Jiangsu Jinhang Machinery Manufacturing Co., Ltd. contributes to both operational savings and environmental responsibility, helping us maintain a competitive edge in the market.

Surface quality is a critical factor in many manufacturing processes. In industries like textiles, plastic films, and synthetic materials, the appearance and smoothness of the final product often determine its commercial value. The Oil-Conductive Heating Roller plays a vital role in achieving consistent and high-quality surface finishes by ensuring that the material being processed is exposed to even heat, preventing imperfections such as warping, unevenness, or surface defects. For Jiangsu Jinhang Machinery Manufacturing Co., Ltd., the ability to provide rollers that offer superior surface quality is a defining feature. The oil-based heating system provides consistent heat across the roller’s surface, which results in more uniform processing. This is especially important when calendering materials such as PVC, synthetic leather, or paper, where even slight variations in temperature can lead to visible defects or subpar finishes. The Oil-Conductive Heating Roller is particularly beneficial in applications where a glossy, high-quality finish is required. When processing materials like plastic films or decorative coatings, a smooth and flawless surface is essential for both aesthetics and functionality. The even heating provided by the oil circulation system ensures that the material is uniformly processed, achieving a high-quality finish without blemishes. The roller’s surface can be treated with various coatings, such as chrome or tungsten carbide, to further enhance its durability and surface smoothness. These coatings, combined with the oil-based heating system, allow for precise control over surface characteristics, helping Jiangsu Jinhang Machinery Manufacturing Co., Ltd. deliver superior products that meet the highest standards of quality.

+86-15371769898

+86-15371769898 [email protected]

[email protected]

English

English русский

русский Deutsch

Deutsch